Shaft alignment

Our company provides shaft alignment measurements and adjusting shafts between the driver and driven units with use of a laser. Capnor has Fixture Laser XA equipment for this purpose.

Precision alignment has proven to prolong the life of bearings in electric motors and the equipment they drive. Accurate alignment decreases mechanical wear on bearings and seals, and cuts down on overall vibration. It makes it possible to reduce power consumption, which in result lowers electricity costs throughout the lifecycle of the machine.

Laser shaft alignment services

Capnor excels in laser shaft alignment, employing state-of-the-art Fixture Laser XA equipment for precision measurements and adjustments. Our specialized service ensures accurate alignment between driver and driven units, enhancing the longevity and efficiency of equipment. Laser shaft alignment significantly contributes to the extended life of bearings in electric motors, reduces mechanical wear, minimizes vibrations, and ultimately lowers power consumption, resulting in substantial electricity cost savings over the equipment’s life cycle. With a commitment to high and repeatable accuracy, Capnor's laser shaft alignment services offer a superior alternative to traditional methods, ensuring optimal performance for units such as pumps, compressors, and industrial power generators.

Laser shaft alignment offered by Capnor guarantees high and repeatable accuracy, and fast execution time compared to traditional methods.

Examples of units that require shaft alignment:

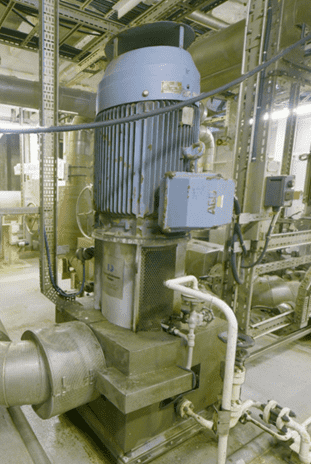

Pumps

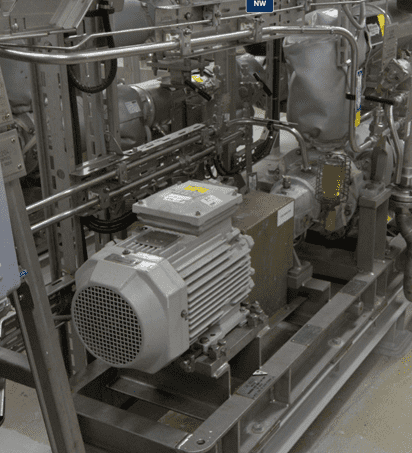

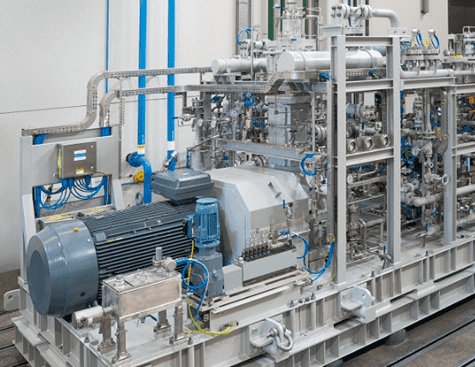

Compressors

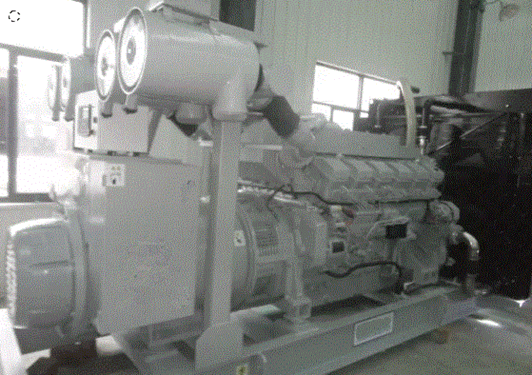

Industrial power generators

FAQ

1. What is the laser alignment technique?

Laser alignment is a precision measurement technique used to align shafts between driver and driven units in machinery and equipment. It involves the use of a laser-based alignment system to accurately determine and adjust the position of rotating shafts, ensuring optimal alignment and performance.

2. How accurate is laser shaft alignment?

Laser shaft alignment is highly accurate, typically achieving alignment tolerances within fractions of a millimeter or micrometer. Modern laser alignment systems offer precision measurements and adjustments, ensuring precise alignment between shafts and minimizing misalignment-related issues such as mechanical wear, vibrations, and energy loss.

3. What are the advantages of laser alignment?

The advantages of laser alignment include:

- Precision: Laser alignment provides highly accurate measurements and adjustments, ensuring optimal alignment between shafts and reducing the risk of mechanical issues.

- Efficiency: Laser alignment is faster and more efficient than traditional alignment methods, allowing for quicker setup, measurement, and adjustment processes.

- Cost Savings: Accurate alignment prolongs the life of bearings and equipment, reduces maintenance costs, minimizes energy consumption, and lowers overall operating expenses.

- Minimized Downtime: Laser alignment minimizes downtime by identifying and correcting alignment issues quickly, preventing costly breakdowns and production interruptions.

- Improved Performance: Proper alignment improves equipment performance, reducing vibrations, noise, and mechanical stress, and enhancing productivity and reliability.

4. What industries use laser shaft alignment services?

Laser shaft alignment services are utilized across various industries, including:

- Manufacturing: For aligning shafts in machinery and equipment used in manufacturing processes.

- Power Generation: For aligning shafts in turbines, generators, and other power generation equipment.

- Oil and Gas: For aligning shafts in pumps, compressors, and rotating machinery used in oil and gas production and refining.

- Marine: For aligning shafts in ship propulsion systems, marine engines, and onboard machinery.

- Mining: For aligning shafts in crushers, conveyors, and other mining equipment.

- Utilities: For aligning shafts in water and wastewater treatment facilities, pumping stations, and distribution systems.

These industries rely on laser shaft alignment services to ensure the reliability, efficiency, and longevity of their equipment and machinery.

Our services

At Capnor, we deliver engineering services that set new standards for quality and efficiency. From precise laser scanning to advanced drone photography, our innovative approach revolutionizes how you make decisions and execute projects. Trust us and focus on your goals. We will handle the rest.

Angielski

Angielski  Polski

Polski